FG filament is not just a filament manufacturer; it is a symbol of innovation and progress in Egypt, Middle East, and Africa. As the first FDM material factory in the region, FG filament is pioneering a new era of 3D printing, offering high-quality filaments with 100% Egyptian manpower.

Setting New PLA Manufacturing Standards

- Premium Quality: FG filaments are unique in their exceptional quality, offering superior performance and reliability. The filament manufacturing process follows the ISO 5425: 2023 specifications, proudly producing filaments with a tolerance of ±0.03 mm. Our products are RoHS certified, meaning that they comply with the “Restriction of Hazardous Substances” to ensure the safety of our workers, customers, and the environment.

- Quality Control: Our factory is equipped with the latest technology to ensure the highest standards of production. Each filament undergoes rigorous testing to ensure that it meets our strict quality standards.

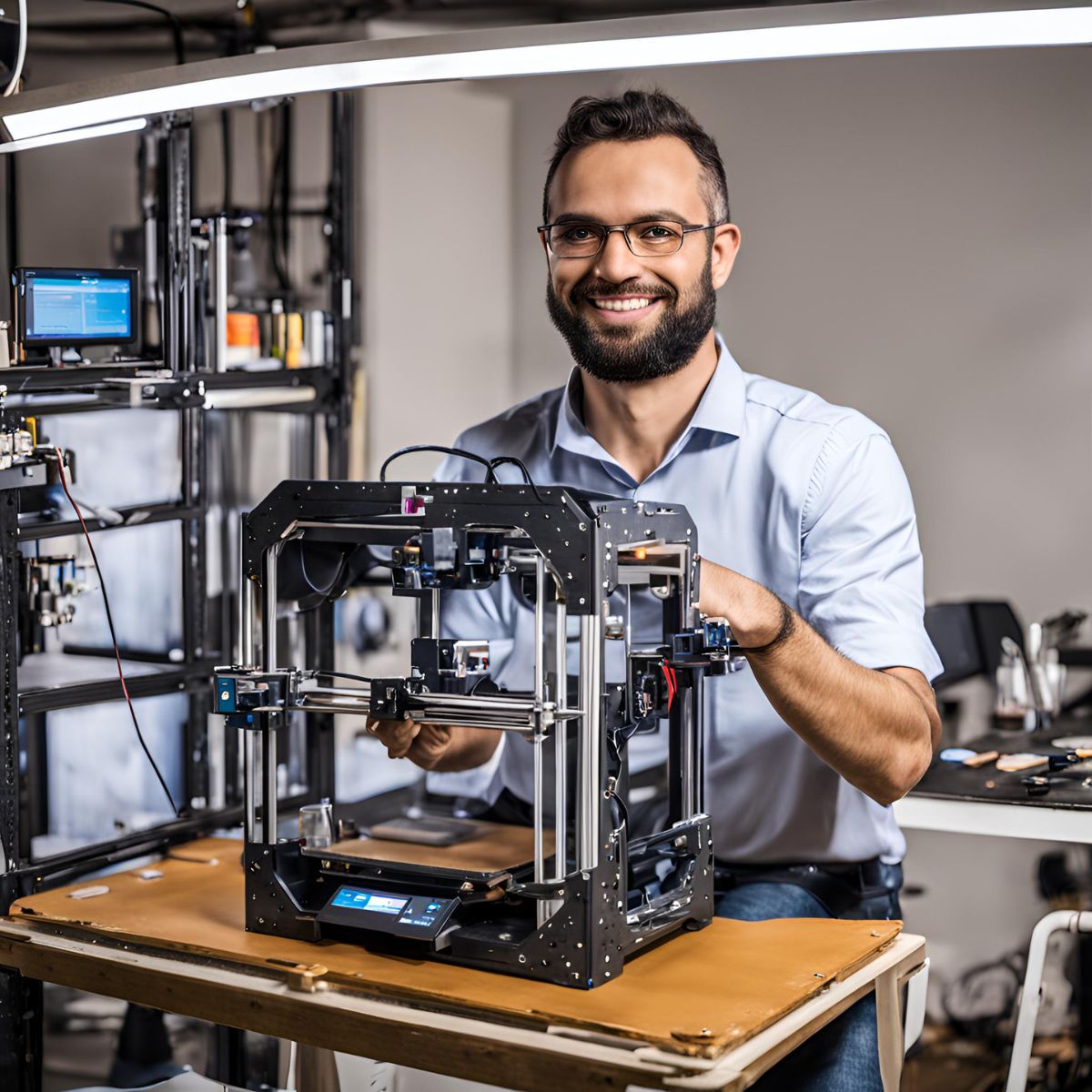

Empowering Egyptian Manpower

FG filament creates new opportunities; by employing 100% Egyptian manpower, we are not just creating jobs but also empowering local talent. We believe in nurturing talent and providing our employees with an opportunity to develop their skills, by offering hands-on training and online courses, that target their specific needs.

Commitment to Sustainability

FG filament is committed to sustainability, therefore produces PLA filaments that are environmentally friendly. PLA can be sourced from organic waste, typically fermented plant starch like corn, sugarcane, or sugar beet pulp.

Leading 3D Printing Revolution

Incepted at Fabrigate, FG filament provides not only the physical material for 3D printing, but also the digital manufacturing expertise in 3D printing, that were implemented in various projects in collaboration with public and private entities.

By manufacturing PLA filaments, FG filament would be supporting a vast variety of industries that involve 3D printing including healthcare, education, entertainment, product manufacturing, and many more. 3D printing will be one of the main building blocks essential for bridging between industries 4.0 and 5.0.